PLASTIC SOCKET WELDING MACHINE HWT 160 SW-S

Product Details:

- Cooling Method Electric

- Condition New

- Insulation Grade Industrial

- Voltage 220-240 Volt (v)

- Click to View more

PLASTIC SOCKET WELDING MACHINE HWT 160 SW-S Price And Quantity

- 2500 INR/Unit

- 1 Unit

PLASTIC SOCKET WELDING MACHINE HWT 160 SW-S Product Specifications

- 220-240 Volt (v)

- New

- Electric

- Industrial

PLASTIC SOCKET WELDING MACHINE HWT 160 SW-S Trade Information

- 7-15 Days

- All India

Product Description

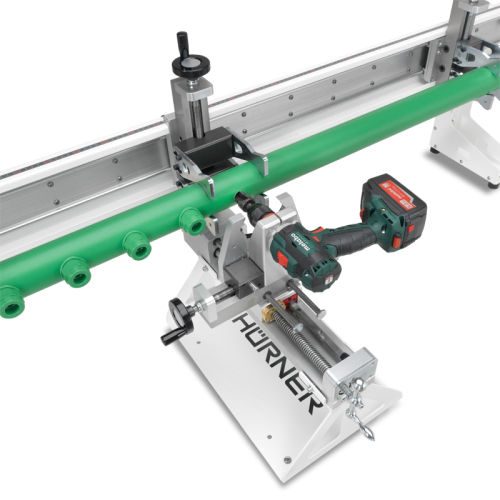

With the HRNER quick mounting system the clamps can be replaced easy as ABC The chassiscarriage without the RH and LH pipealigning clamps can be removed from its steel frame by simply loosening 4 mounting screws and can then be used in areas that are hard to reach or overhead

Both the operation of the clamps for the straight pipe and the saddle fitting and the movement of the carriage for the latter are implemented as using ergonomically designed handwheels Additionally the motion handwheel can be removed easily to move the clamping chassiscarriage with a common power tool cordless drillscrewdriver as its drive

A special mention deserve the heating element seat next to the chassis for clamping the saddle fitting on which to place the heating element and the two freely adjustable depth setpoints The easy insertion and safe and swift removal of the heating element including centering and an autodetaching step in the changeover stage bring a use as convenient as to be considered unique

The insertion depth setpoints provide on the one hand consistent fusion depth and welding position and on the other shorter length of movements thus faster changeover

Special octagonal clamps for branchoff fittings of various wrench sizes are also available

TECHNICAL SPECS

HWT 160 SWS PN 416000000

OPERATING RANGE

straight pipeline OD 40 160 mm

branchoff fitting OD 20 90 mm

MATERIALS PP PPR PEHD others upon request

HEATING ELEMENT TEMPERATURE RANGE

260C 500F 200C 270C 392F 518F

MACHINE DIMENSIONS W H D

360 650 610mm

MACHINE WEIGHT 21 kg

HWT 160 SWS

INCL RH LH MOVABLE PIPEALIGNING SUPPORTS PN 416000001

OPERATING RANGE

straight pipeline OD 40 160 mm

branchoff fitting OD 20 90 mm

MATERIALS PP PPR PEHD others upon request

HEATING ELEMENT TEMPERATURE RANGE 260C 500 200C 270C 392F 518F

MACHINE FOOTPRINT W H D

W LATERAL PIPE SUPPORTS

2000 650 610 mm

MACHINE WEIGHT 43 kg

HEATING ELEMENT ELECTRONICALLY CONTROLLED 230 V

FOR SADDLE WELDING SOCKETSSPIGOTS 20 63 MM

PN 416074000

HEATING ELEMENT ELECTRONICALLY CONTROLLED 230 V

FOR SADDLE WELDING SOCKETSSPIGOTS 63 90 MM

PN 416074001

HEATING ELEMENT ELECTRONICALLY CONTROLLED 110 V

FOR SADDLE WELDING SOCKETSSPIGOTS 20 63 MM

PN 416074002

HEATING ELEMENT ELECTRONICALLY CONTROLLED 110 V

FOR SADDLE WELDING SOCKETSSPIGOTS 63 90 MM

PN 416074003

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'SOCKET WELDING' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese