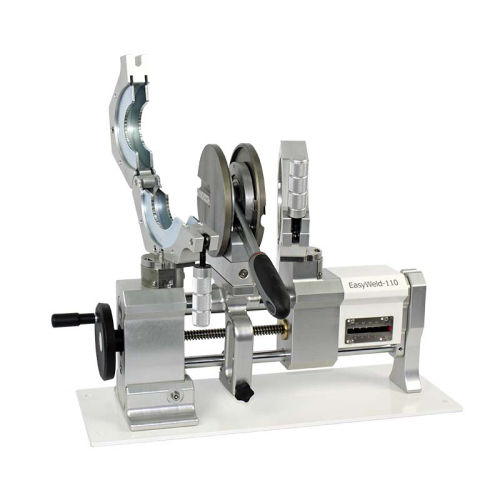

HURNER WORKSHOP MACHINE EASYWELD 110 (T)

Product Details:

HURNER WORKSHOP MACHINE EASYWELD 110 (T) Price And Quantity

- 1 Number

- 1 INR/Number

HURNER WORKSHOP MACHINE EASYWELD 110 (T) Trade Information

- All India

Product Description

1) pipes and fittings for all pressure ratios, from O.D. 20 through 110 mm (Tees O.D. 20 through 90 mm). This system enables a unique way of handling that is simply unavailable anywhere else. For welding operations, it offers all the advantages of a mobile butt-welding system that is user-friendly and handy enough to be at home at any place, both on worksites and in workshops.

The clamps on the machine chassis are available with horizontal and, optionally, with vertical adjustability, enabling pre-welding precision placement in both dimensions, which is particularly important for optimum results in tee and segmented-bend welding applications. Its compact and lightweight design makes the HRNER EasyWeld 110 (T) the optimum choice for overhead welding operations. The manufacture of fittings is possible thanks to the clamps on the chassis bilaterally swiveling by up to 15 deg. each. For tee jointing operations, clamps for the chassis are available that are set at a 45 deg. angle.

The machine as a whole with its frame is mounted on a heavy-duty, powder‘coated base panel. Part of the system™s standard delivery is the perfectly ergonomically designed manual facing tool with the possibility of horizontal adjustment and a two-edge usable facing blade. The facing tool with electrical drive, too, features horizontal adjustability and a two-edge usable blade, all of which extend its useful life. The electronically controlled, PTFE-coated heating element features an integrated temperature control.

TECHNICAL SPECS

| TECHNICAL SPECS | EASYWELD 110 W/ HORIZONTAL ADJUSTABILITY AND MANUAL FACING TOOL | EASYWELD 110 W/ HORIZONTAL ADJUSTABILITY AND POWER FACING TOOL | EASYWELD 110 T W/ HORIZONTAL AND VERTICAL ADJUSTABILITY AND POWER FACING TOOL |

| P/N 200-260- | -051 | -052 | -152 |

| OPERATING RANGE, O.D. | 20 - 110 mm | 20 - 110 mm | 20 - 110 mm |

| OPERATING RANGE FOR TEE WELDING |

- |

- | 20 - 90 mm |

| POWER SUPPLY | 230 V / 110 V1), 50 Hz | 230 V / 110 V1), 50 Hz | 230 V / 110 V1), 50 Hz |

| RATED POWER HEATING ELEMENT/FACING TOOL | 800 W / - | 800 W / 500 W | 800 W / 500 W |

| OVERALL WEIGHT INCLUSIVE OF ALL COMPONENTS2) | 31.9 kg | 35.4 kg | 38.4 kg |

| REDUCER INSERTS, 8 SEMI-CIRCULAR JAWS PER SIZE | 20, 25, 32, 40, 50, 63, 75, 90 mm3) | 20, 25, 32, 40, 50, 63, 75, 90 mm3) | 20, 25, 32, 40, 50, 63, 75, 90 mm3) |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'WORKSHOP SYSTEMS' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese